MZ SERIES CAM CLUTCHES

MZ SERIES CAM CLUTCHES

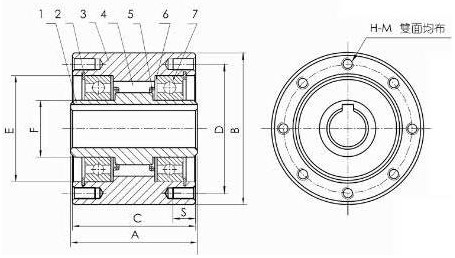

1. Inner ring 2. Collar 3. Outer ring 4. Cam 5. Spring 6. Baffle 7. Bearing

Other introductions:

Size and performance

| Model | Max.Torque (N.M) | Max.Overrunning | Max.Indexing (cycle/min) | Stock Bore Size | A | B | C | D | E(m6) | F | G | H-M cavity | S | Weight(kg) | ||

| Inner Race | Outer Pace | Stock Bore Size | Keyway | |||||||||||||

| MZ15 | 186 | 1800 | 900 | 150 | 15 | 5×2.3 | 62 | 68 | 60 | 58 | 47 | 25 | 5.5 | 6×M5×P0.8 | 10 | 1.4 |

| MZ17 | 215 | 1700 | 800 | 150 | 17 | 5×2.3 | 66 | 75 | 64 | 64 | 52 | 28 | 6.3 | 6×M5×P0.8 | 10 | 1.8 |

| MZ20 | 323 | 1600 | 700 | 150 | 20 | 6×2.8 | 67 | 80 | 65 | 68 | 55 | 30 | 7.6 | 6×M5×P1.0 | 12 | 2.0 |

| MZ30-22 | 735 | 1500 | 500 | 150 | 22 | 6×2.8 | 82 | 100 | 80 | 88 | 75 | 45 | 8.9 | 6×M8×P1.25 | 16 | 3.7 |

| MZ30-25 | 25 | 8×3.3 | ||||||||||||||

| MZ30 | 30 | 10×3.3 | ||||||||||||||

| MZ35 | 1080 | 1400 | 300 | 150 | 35 | 10×3.3 | 87 | 110 | 85 | 95 | 80 | 50 | 8.7 | 6×M5×P1.25 | 16 | 4.8 |

| MZ45-40 | 1620 | 1400 | 300 | 150 | 40 | 12×3.3 | 92 | 125 | 90 | 110 | 95 | 60 | 8.4 | 6×M5×P1.25 | 16 | 6.2 |

| MZ45 | 45 | 14×3.8 | ||||||||||||||

| MZ60-50 | 2710 | 250 | 150 | 50 | 14×3.8 | 102 | 155 | 100 | 140 | 125 | 80 | 9.1 | 6×M5×P1.25 | 16 | 10.2 | |

| MZ60-55 | 55 | 16×4.3 | ||||||||||||||

| MZ60 | 60 | 18×4.4 | ||||||||||||||

| MZ70-65 | 3040 | 1100 | 250 | 150 | 65 | 18×4.4 | 105 | 175 | 103 | 145 | 145 | 95 | 8.6 | 6×M5×P1.25 | 16 | 13.2 |

| MZ70 | 70 | 4.9 | ||||||||||||||

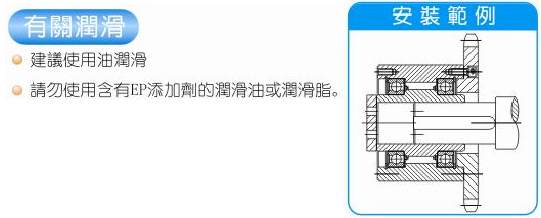

Installation and use

The MZ series cam clutch is equipped with dust-proof bearings at both ends, which have been injected with special lubricating grease inside and do not require lubrication during use.

When cooperating with a pulley, gear, or sprocket, insert the clutch into the hole of the pulley, gear, or sprocket (with JIS standard f6 tolerance) and tighten the bolt (high tensile strength) into the tooth hole on the clutch end face.

External loads need to be supported by other devices and cannot be directly applied to the cam clutch.

The connection between the clutch and the shaft can only use flat keys, do not use tapered keys.

When installing the clutch on the shaft, the thrust should be applied to the inner ring of the clutch, not to the outer ring.

The working environment temperature of this series of cam clutches is -5 ℃ to 40 ℃